Scaglia Indeva® has been involved in low-cost automation since 1980 and has been designing and manufacturing Automatic Guided Vehicles (AGV) since 2000.

MAIN FEATURES:

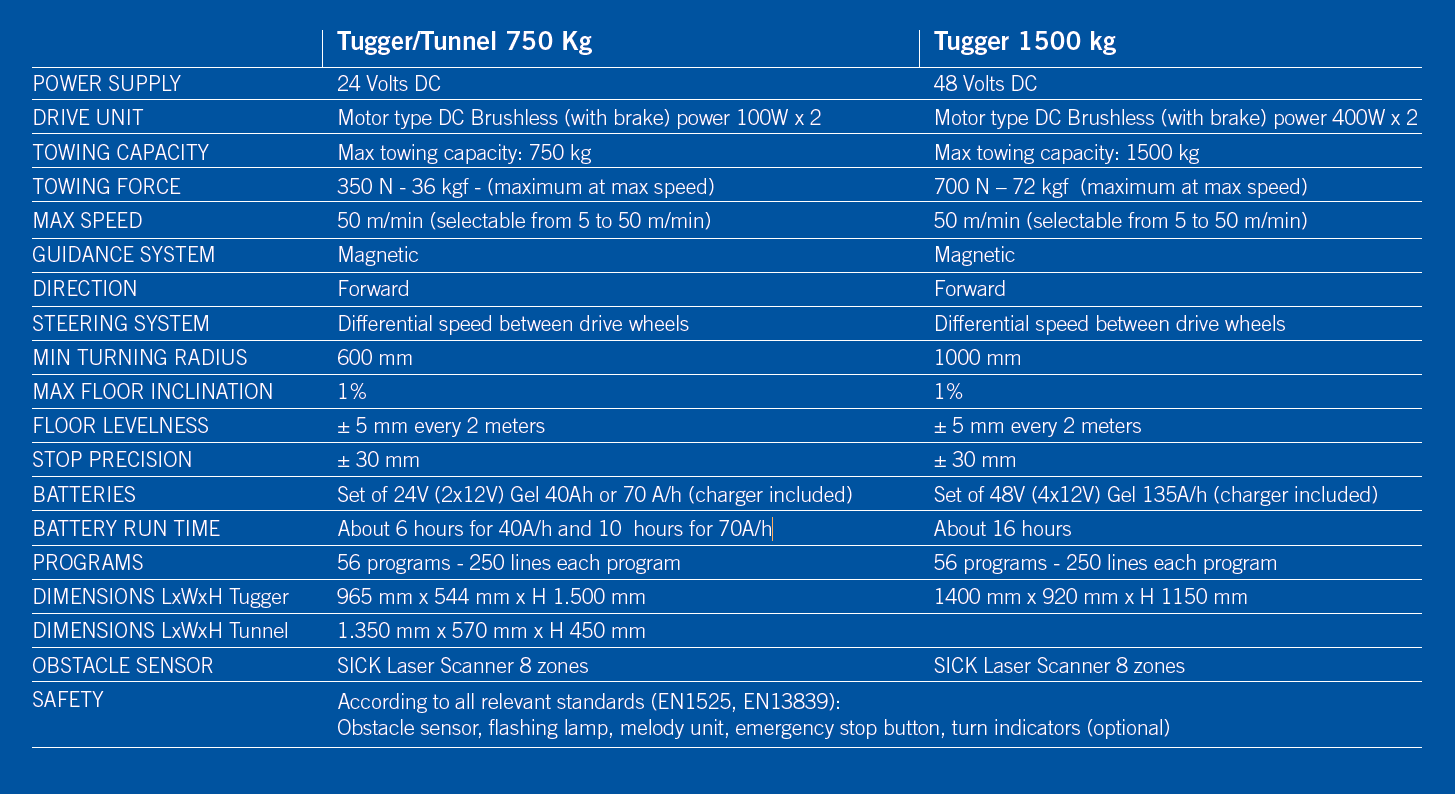

STANDARD MODELS:

Indeva Tugger AGV – 750 kg – 1500 kg

Most common type, typically used for towing trolleys/trolleys.

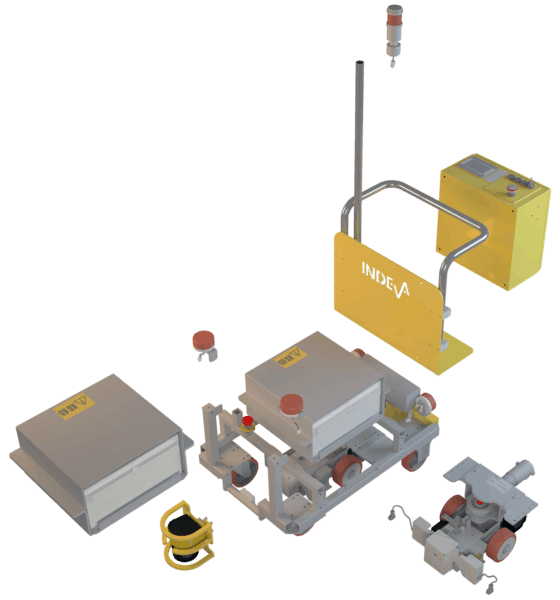

Indeva Tunnel AGV – 750 kg

Low profile design. Its design allows to move underneath the trolleys to be transported, connected using an automatic PIN-Hook system, and then automatically released at the predetermined location when it reaches its destination.

Below are some of the companies that have used INDEVA® AGVs with satisfaction:

In the automotive field:

Non automotive field:

Advantages of magnetic tape AGVs:

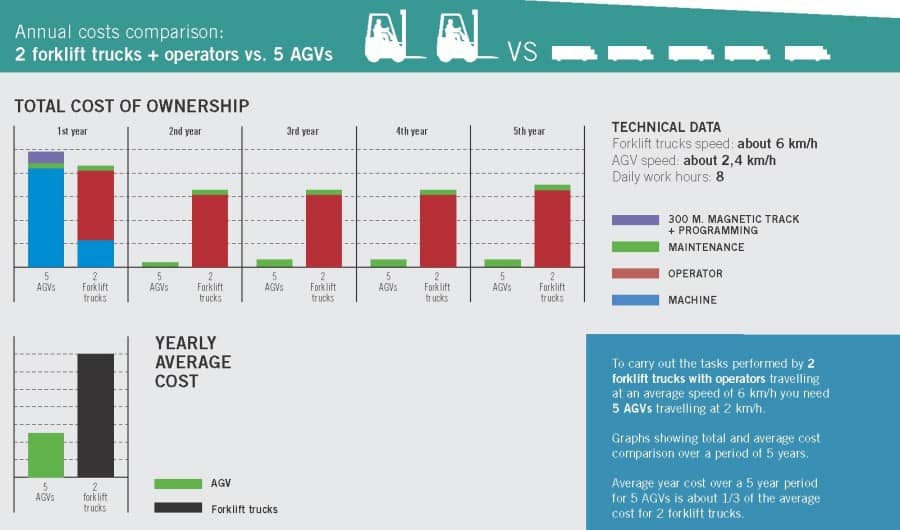

Scaglia Indeva® has been involved in low-cost automation since 1980 and has been designing and manufacturing Automated Guided Vehicles (AGVs) since 2000. INDEVA® AGV solutions are designed for companies that want to operate their internal material handling processes efficiently while minimizing human resources. Lean Technology Hungária Kft. is the official distributor of INDEVA systems in Hungary, providing full technical support from implementation to operation.

INDEVA AGVs operate using magnetic tape guidance, are simple to install, and the routes can be easily modified later—even via a touchscreen—once the system is set up.

The stable structure and proven mechanical components ensure long-term, trouble-free operation, while the low investment cost results in a fast return on investment (ROI). The range includes the Indeva Tugger AGV (750–1500 kg) for heavier transport and the low-profile Indeva Tunnel AGV (750 kg), which automatically hooks onto and unhooks from the trolley at the destination.

Automated tugs play a vital role in developing modern intralogistics systems, particularly in lean manufacturing models and just-in-time production structures. Their application enables precise, scheduled material flow from the receipt of raw materials all the way to the assembly lines. This continuity is especially important in environments where production scheduling is tight and requires predictable logistical support.

INDEVA AGVs are widely used in the automotive industry, electronics manufacturing, as well as the food and pharmaceutical industries. The system effectively reduces manual material handling, eliminates bottlenecks, and mitigates disruptions caused by human error. Companies such as Suzuki, APTIV, Fiat Auto, and Carl Zeiss have already successfully integrated INDEVA AGV technology into their daily production and logistics operations.

The use of automated tugs has a direct impact on production flexibility and time management efficiency. AGVs travel along predetermined routes without interruption, significantly reducing downtime and making material flow more predictable. This is crucial where the pace of production does not allow for delays or errors.

Since the system automates repetitive, low-value-added transport tasks, human labor can focus on activities that require expertise or decision-making.

Work organization can be restructured, reducing the burden on workers while increasing productivity and employee satisfaction. The magnetic tape technology is easily expandable, allowing the fleet of automated tugs to be flexibly adjusted to future production needs.

This website uses cookies to enhance your experience. Some are essential for site functionality, while others help us analyze and improve your usage experience. Please review your options and make your choice.

If you are under 16 years old, please ensure that you have received consent from your parent or guardian for any non-essential cookies.

Your privacy is important to us. You can adjust your cookie settings at any time. For more information about how we use data, please read our privacy policy. You may change your preferences at any time by clicking on the settings button below.

Note that if you choose to disable some types of cookies, it may impact your experience of the site and the services we are able to offer.

Some required resources have been blocked, which can affect third-party services and may cause the site to not function properly.