Electric and Pneumatic Manipulators

Lean Technology Hungária Kft. is the official and exclusive distributor of INDEVA equipment in Hungary and Serbia.

Why choose an INDEVA manipulator?

These are lifting technology devices typically used in manufacturing, industrial environments, and logistics sectors for handling heavy loads (20–320 kg) for ergonomic or safety reasons.

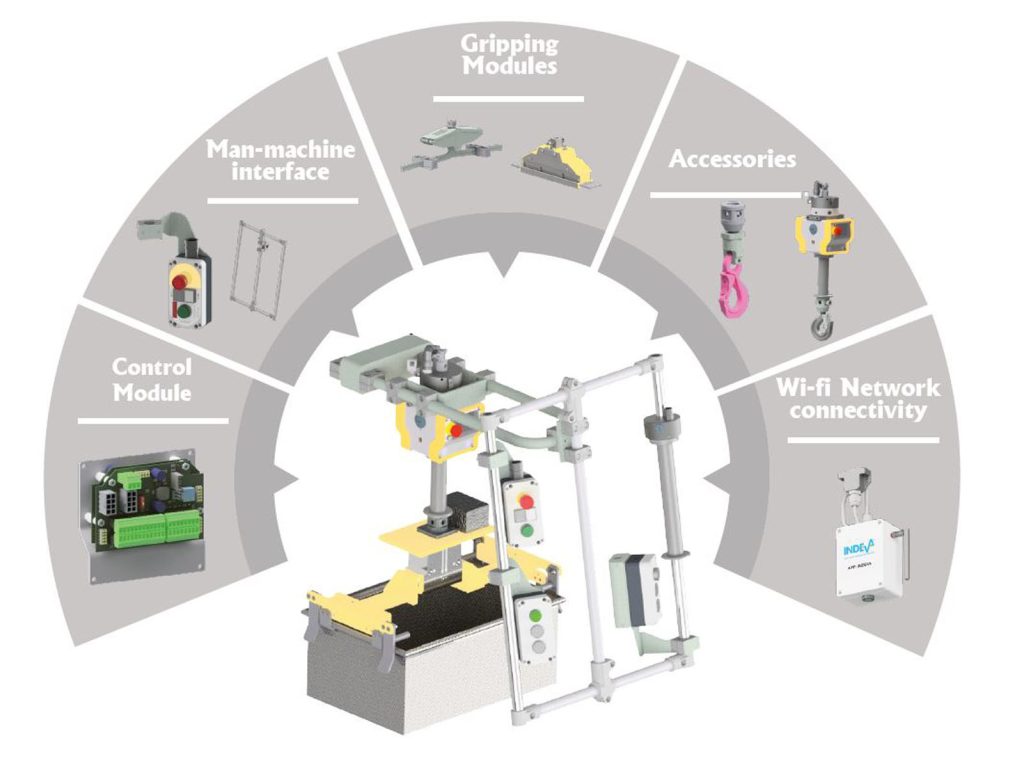

They are designed to move and position loads precisely, quickly, and accurately, and are highly customizable for the specific application. Numerous versions of standard INDEVA tools can be used with the products, but there is also the possibility for custom tool design and manufacturing.

Compared to traditional cranes and chain hoists, they offer greater flexibility, safety, and ergonomic benefits. Compared to automated robots, they are typically smaller, more precise, and better suited for applications requiring greater human control and customization.

LIFTRONIC® Electric Manipulators

LIFTRONIC® manipulators are the most advanced versions of load-balancing equipment. These devices are controlled by a microprocessor instead of traditional pneumatic control, meaning they are not subject to the limitations of older technologies. As a result, they offer higher reliability and performance.

Operators can move weights confidently with high speed and precision. The advanced control system continuously senses load changes and the operator’s movements, making the operation intuitive and effortless. Consequently, when using an electric manipulator, the worker experiences a sensation as if they were lifting only grams, even when handling objects weighing dozens of kilograms.

PN – Pneumatic Manipulators

LIFTRONIC AIR represents the latest generation of industrial manipulators in the INDEVA® family, combining the power of traditional pneumatic manipulators with INDEVA® intelligence. Lifting is performed by a pneumatic cylinder, but they operate with electronic control.

They feature a rigid parallelogram arm structure and are typically used for off-center lifting or tasks where the movement requires a rigid suspension.

In which industries are they applied?

Electric and pneumatic manipulators are used across numerous industries, such as the automotive, food, pharmaceutical, and electronics assembly sectors. They represent a particularly advantageous solution for repetitive, precise, and physically demanding tasks, such as palletizing or moving sensitive components.

A safer, more efficient working environment

Their ergonomic design not only serves the comfort of the workers but also contributes to the reduction of workplace accidents and the increase of productivity. The customizability of various gripping tools ensures that the device always fits the technical requirements of the given task.

Operational and economic benefits

The low energy consumption, reliable control, and fast learning curve of the electric manipulator significantly reduce operating costs. The pneumatic manipulator offers simpler maintenance and a more robust structure, making it a cost-effective and durable solution, especially in industrial environments.

Why Lean Technology?

Lean Technology’s expert team ensures the selection of the optimal technology from the beginning to the end of the project, taking into account the expectations of Lean-oriented manufacturing processes. A well-chosen manipulator not only relieves the workforce but also creates a competitive advantage by increasing production efficiency.