TRUCK TRAILER

BOX STORAGE

SPECIFIC ROTATING STRUCTURE

WELDED CHASSIS

WELDED CASTOR SHELF

WELDED TRACK ROLLER

hegesztett nyomtávkövető

WELDED STRUCTURE

WELDED TROLLEY

WELDED WAGON FRAME

PLASTIC TROLLEY

TRACKED TROLLEY

SPRING LOADED BALENCER TROLLEY

TABLE TARE

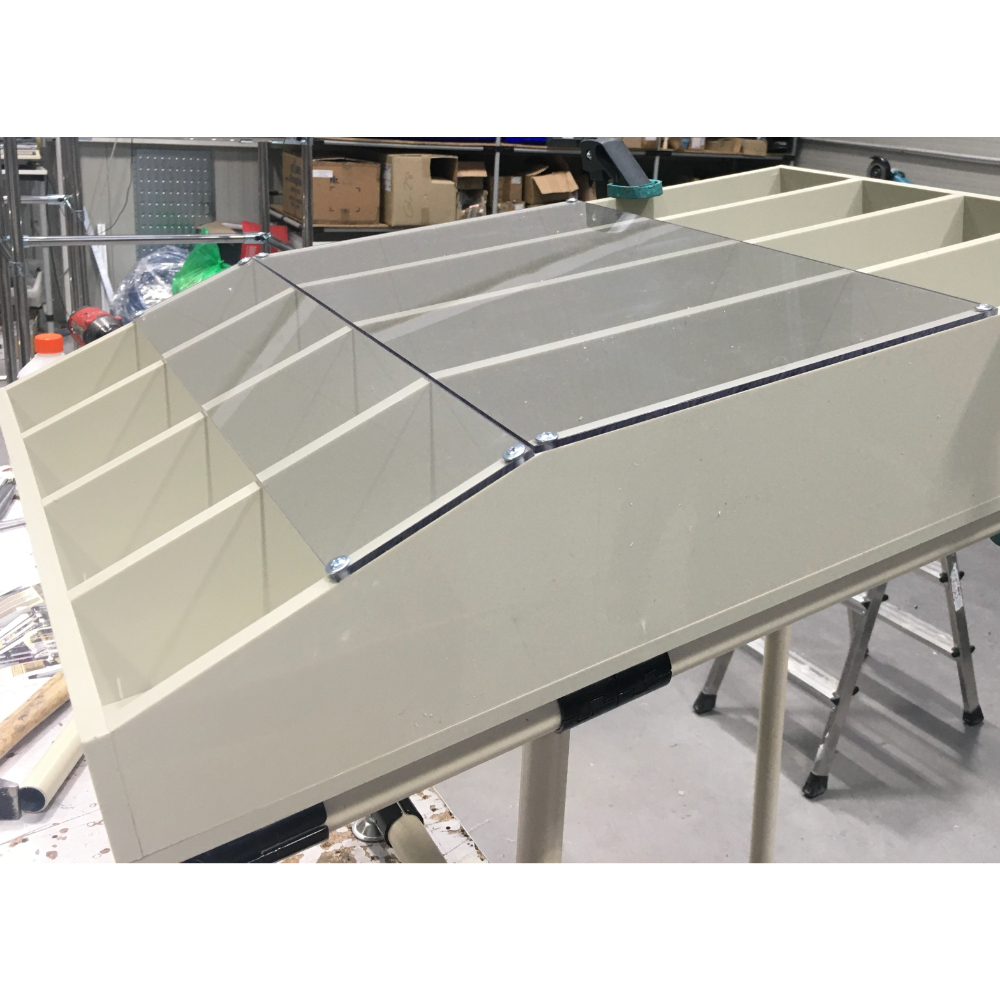

WEDGE STORAGE

STORAGE STAND

STORAGE TROLLEY

STORAGE CUSHION

COTBED

BATHTUB

CHANGING TABLE

SPRING LOADED TROLLEY

TRACK FOLLOWING TROLLEY

The special structures available in Lean Technology’s portfolio provide reliable, long-term solutions in the fields of industrial material handling, storage, and organization.

Special structures are not uniform; their essence lies in their ability to operate efficiently, tailored specifically to target tasks.

When daily loads are high and structural reliability is paramount, welded carts are an excellent choice. These tools are developed to operate for years without maintenance. The rigid frame structure maintains its original shape over the long term, eliminating concerns about unstable movement or fitting issues.

The purpose of track-following systems is to provide controllable, traceable movement even in confined spaces, making them particularly useful in narrow aisles or automated material handling routes. These structures precisely follow the designated path, preventing collisions and bottlenecks, thereby accelerating internal logistics.

These storage solutions help structure materials, components, or tools. The containers are modular, easy to stack, and support transparent, fast access according to lean logic. Additionally, they are ideal for separating and sorting smaller batches.

Special spring-loaded or rotating structures help operators access materials in the most comfortable position at all times. An automatically self-leveling (spring-loaded) tray or a rotatable storage unit significantly speeds up work while reducing the physical strain caused by bending or twisting.

Standard solutions often do not fit the real needs of industrial production precisely. Custom or welded structures, however, are made exactly where and how they are needed: in terms of size, design, load capacity, and function alike.

Special structures not only enable faster and more efficient work but also contribute to the comfort and safety of workers. Thanks to their durable, stable design, they require less frequent maintenance, significantly reducing downtime and upkeep costs.

Whether it involves assembly line supply, warehousing, or mobile storage units, special structures are created through individual design. The Lean Technology team provides the necessary technical and advisory background from the first consultation through to implementation.

Lean Technology’s goal is to ensure our clients receive stable, efficient, and easy-to-operate systems in the long run. A well-designed, properly executed structure is not only convenient in the short term but remains an active and reliable part of the system even years later.

This website uses cookies to enhance your experience. Some are essential for site functionality, while others help us analyze and improve your usage experience. Please review your options and make your choice.

If you are under 16 years old, please ensure that you have received consent from your parent or guardian for any non-essential cookies.

Your privacy is important to us. You can adjust your cookie settings at any time. For more information about how we use data, please read our privacy policy. You may change your preferences at any time by clicking on the settings button below.

Note that if you choose to disable some types of cookies, it may impact your experience of the site and the services we are able to offer.

Some required resources have been blocked, which can affect third-party services and may cause the site to not function properly.