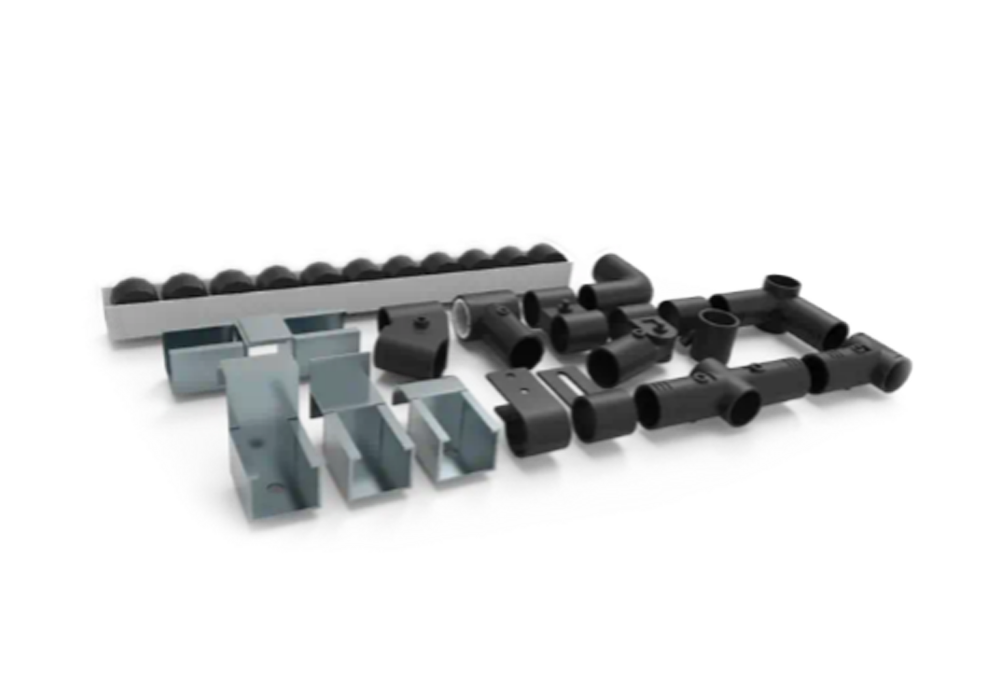

High wear resistant plastic-coated and stainless steel tubes, anodized or painted aluminium tubes, steel connectors, roller conveyors, guides, wheels and all accessories necessary for the construction of an ergonomic workstation, production cell or production unit designed according to the LEAN principle, even in ESD design.

The units made from our components are simple to design, quick to assemble and fully recyclable in case of changes in the production structure.

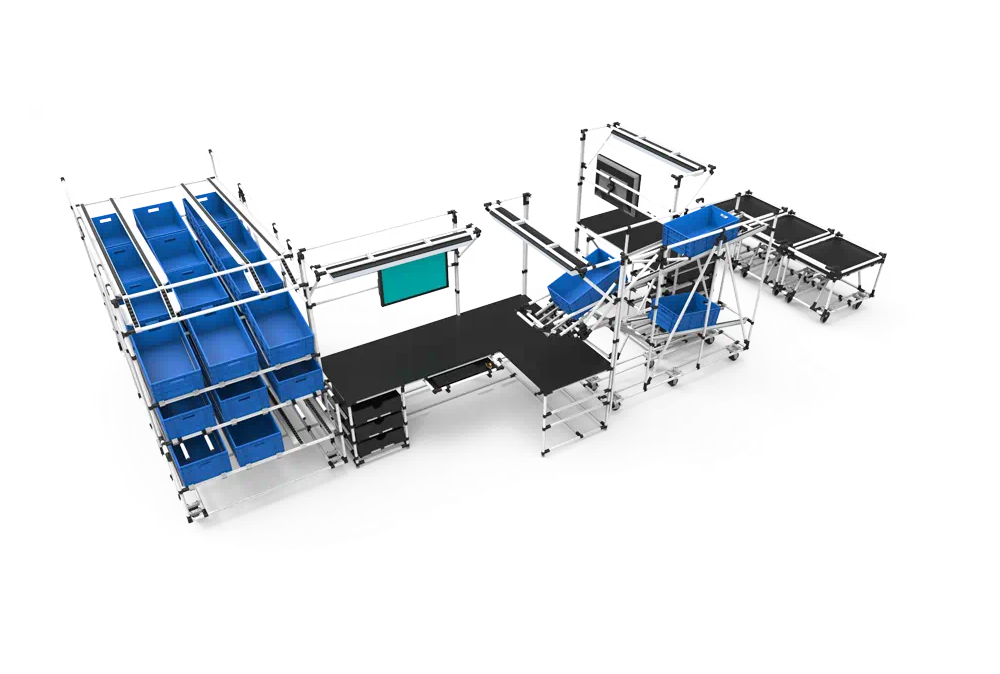

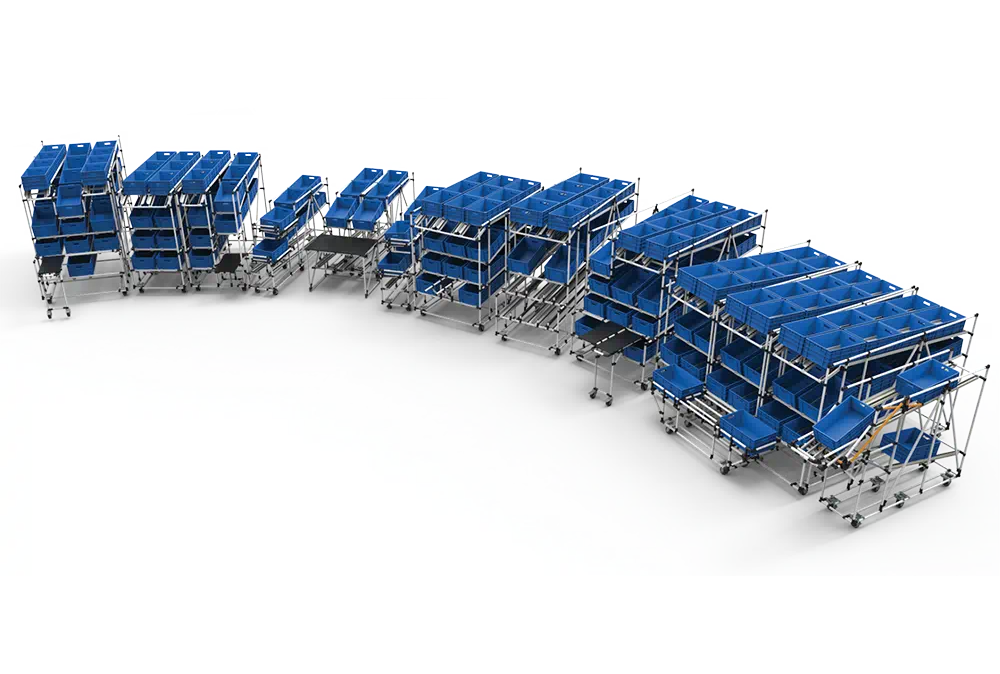

The modular system is a tool for optimizing manufacturing processes and implementing Lean Manufacturing, Kaizen, Kanban and FIFO. With our modular system, any application can be built quickly and easily. Workstations, Kanban and gravity racks, racks with roller rails. Modular systems can thus be used not only in the warehouse but also in production.

Anyone who moves in the world of continuous improvement and implementation of Lean production methods has probably come across the term “Kaizen” many times.

Kaizen is a method of incremental improvement that focuses on the gradual optimisation of processes and workflows, increasing quality and reducing scrap, saving material and time, leading to cost reduction or safety at work, or reducing accidents at work. Eliminating waste, improving quality and efficiency are never-ending processes.

Kaizen is a method of incremental improvement that focuses on the gradual optimisation of processes and workflows, increasing quality and reducing scrap, saving material and time, leading to cost reduction or safety at work, or reducing accidents at work. Eliminating waste, improving quality and efficiency are never-ending processes.

Kaizen means continuous improvement. It means not being satisfied with the way things are, but constantly looking at how to improve and make them more efficient. As a result, Kaizen is a continuous growth of production standards. In the workplace, KAIZEN means continuous improvement, involving everyone – managers and subordinates alike.

Success in a highly competitive environment requires not only a quality product, but also a continuous improvement in the efficiency of production and management processes. Lean management and Kaizen best practices effectively reduce waste, save time and manpower, and gradually contribute to higher profits.

Our modular system can be a good tool to achieve your continuous improvement processes.

A well thought-out workspace, designed to make production operations work more efficiently, is the cornerstone of any successful manufacturing, logistics or warehousing company. A flexible, highly durable and easily adjustable modular tube system tailored to the workplace. We place great emphasis on streamlining production and reducing operating costs.

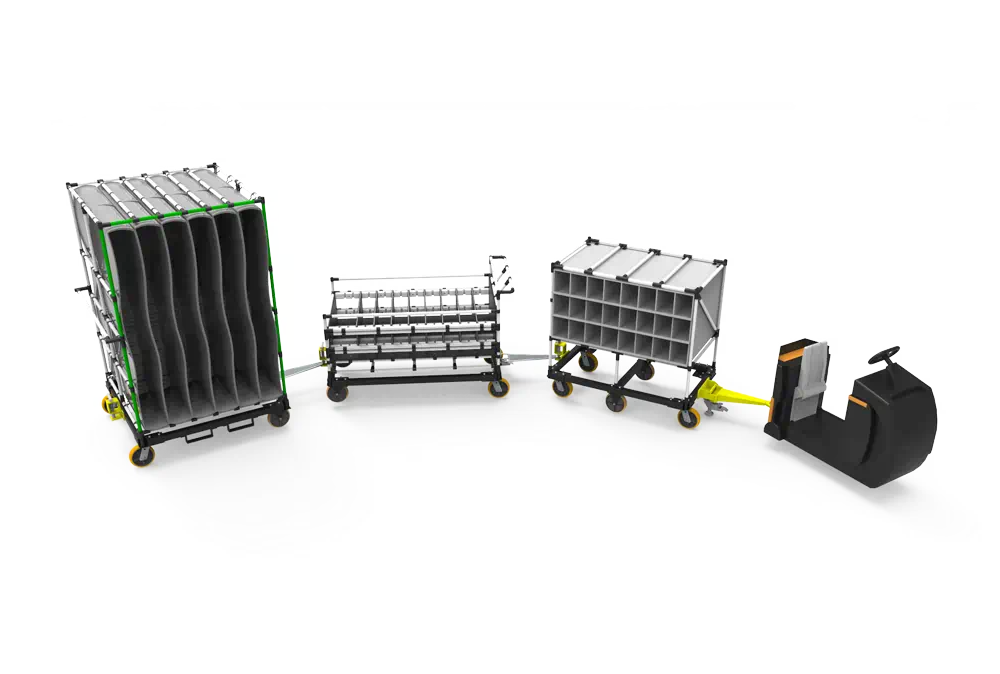

Modular transport and material trolleys for the internal supply of manufacturing plants. Trolleys for order picking of storage materials and orders, trolleys with textile shelves or racks for hanging various parts and finished products. Lean trolleys are suitable for shortening in-process times, simplifying material handling and reducing inventories in the manufacturing plant.

Modular transport and material trolleys for the internal supply of manufacturing plants. Trolleys for order picking of storage materials and orders, trolleys with textile shelves or racks for hanging various parts and finished products. Lean trolleys are suitable for shortening in-process times, simplifying material handling and reducing inventories in the manufacturing plant.

Stable, high-quality, modular workbenches are an important cornerstone of a manufacturing company. They provide a safe and efficient working environment that increases productivity and reduces the risk of accidents. Our modular workbenches offer flexibility as they can be tailored to individual tasks and needs. A stable workbench is essential for precise work and safe storage of tools, which is a requirement for producing high quality products. Choosing the right quality workbench will ensure long life and reduce the risk of breakdowns, saving you time and money in the long run.

Flexible and stable parts for modular tube and aluminium profile systems, ideal for simplifying production and internal logistics. The individual components ensure constant stability, quick and easy adjustment of the entire system, ease of use or long service life. The colour variations of each tube allow a great choice according to your personal preferences.

Lean Technology offers a wide product portfolio in the field of modular tube and joint systems, enabling our partners to create lean-based manufacturing cells or workstations quickly and cost-effectively. Available materials include high wear-resistance plastic-coated and stainless steel pipes, anodized aluminum elements, steel connectors, as well as industrial rollers and guides.

These systems are easy to design, quick to assemble, and can be reused at any time if production process changes require it. They are also available in special ESD-protected versions, ensuring safe application in sensitive electronic or precision industrial environments.

Modular tube systems are not just a collection of parts; they are efficiency-enhancing tools. They allow for the rapid construction of almost any internal logistics or manufacturing application, whether it is a workstation, FIFO rack, Kanban rack, or gravity roller system.

The modules available in Lean Technology’s range easily adapt to the changing rhythm of lean production. If the manufacturing structure changes, the components can be reconfigured, representing a long-term economical and sustainable solution.

One of the greatest strengths of tube-frame structures is flexibility. Thanks to their modular design, they can be quickly expanded or modified according to current production tasks. They are widely used in the automotive industry, electronics assembly, logistics, and warehousing.

Through ease of assembly, small footprint, and long service life, these systems are not only efficient but also offer a sustainable, low-maintenance solution for modern industry.

Kaizen and Lean principles are closely intertwined; both strive to improve efficiency and eliminate waste. The Kaizen philosophy represents continuous development through small steps, resulting in increased quality, reduced scrap, and an improved working environment.

Modular tube systems perfectly support the practical implementation of these principles. Since they are easily modified, they provide an opportunity for employees to shape their own workstations based on their own suggestions—one of the fundamental pillars of the Lean mindset.

Lean Technology’s modular tube solutions help to continuously raise production standards while making company operations more flexible. Through recyclable, easily transformable elements, the working environment can be constantly improved with minimal cost and downtime.

This type of system not only increases efficiency but also builds culture: employees become active participants in the development process. Thus, the modular tube system becomes not only a technical tool but a strategic asset for long-term success.

This website uses cookies to enhance your experience. Some are essential for site functionality, while others help us analyze and improve your usage experience. Please review your options and make your choice.

If you are under 16 years old, please ensure that you have received consent from your parent or guardian for any non-essential cookies.

Your privacy is important to us. You can adjust your cookie settings at any time. For more information about how we use data, please read our privacy policy. You may change your preferences at any time by clicking on the settings button below.

Note that if you choose to disable some types of cookies, it may impact your experience of the site and the services we are able to offer.

Some required resources have been blocked, which can affect third-party services and may cause the site to not function properly.