INTERNAL PARTITION

OTHER BOX

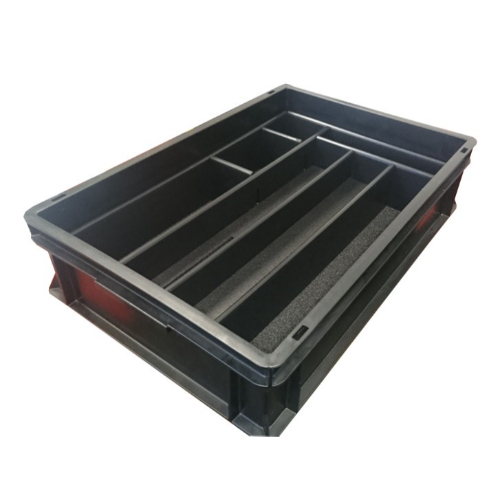

INSERT

INSERT

KITTING BOX

KITTING BOX

Inserts play a fundamental role in safe storage and transport. A well-designed insert protects the product and makes the entire material handling process more transparent, faster, and more accurate.

The role of inserts is essential for the undamaged and organized transport of a component or product.

Inserts are made to perfectly fit the interior of the box and the shape of the placed product. This precise fit prevents goods from shifting, turning, or colliding with each other during transport. This is especially critical in cases involving fragile, high-value, or precision mechanical components.

A well-designed insert not only protects but also creates order within the box. Every part has its own place, allowing workers to find what they are looking for quickly and clearly. There is no unnecessary searching, resulting in fewer errors and less scrap. This type of transparency saves time and energy on a daily basis, which represents a significant advantage in a production environment.

Selecting the right insert affects the safety, speed, and sustainability of daily operations.

An insert works well only if it fits both the product and the container perfectly. If it is too tight, removal is difficult; if it is too loose, the product may shift and become damaged. This is particularly important for sensitive, precision parts, where even a tiny fitting error can cause scrap or machine downtime.

The choice of the insert’s material fundamentally determines long-term usability and product protection. A well-chosen material is simultaneously durable, strong, and flexible. It must withstand daily loads while being capable of absorbing shocks and vibrations.

This is especially important during transport, where the insert must function as mechanical protection. Additionally, it must resist environmental effects: it should not deform or lose its function due to moisture, temperature fluctuations, or exposure to chemicals.

When designing inserts, one must always adapt to the requirements of the specific industry. In the food industry, for example, easy cleanability and hygiene standards are the benchmarks, while in the automotive or electronics industries, anti-static or chemical-resistant materials are often required.

Lean Technology offers comprehensive, customized insert solutions. Whether it is a solution fitting into a standard system or a completely unique requirement, the goal is always the same: safe, transparent, and efficient storage where every part is in its place.

This website uses cookies to enhance your experience. Some are essential for site functionality, while others help us analyze and improve your usage experience. Please review your options and make your choice.

If you are under 16 years old, please ensure that you have received consent from your parent or guardian for any non-essential cookies.

Your privacy is important to us. You can adjust your cookie settings at any time. For more information about how we use data, please read our privacy policy. You may change your preferences at any time by clicking on the settings button below.

Note that if you choose to disable some types of cookies, it may impact your experience of the site and the services we are able to offer.

Some required resources have been blocked, which can affect third-party services and may cause the site to not function properly.